Description

Key Technical Features & Advantages

- Mechanical Strength & Impact Resistance

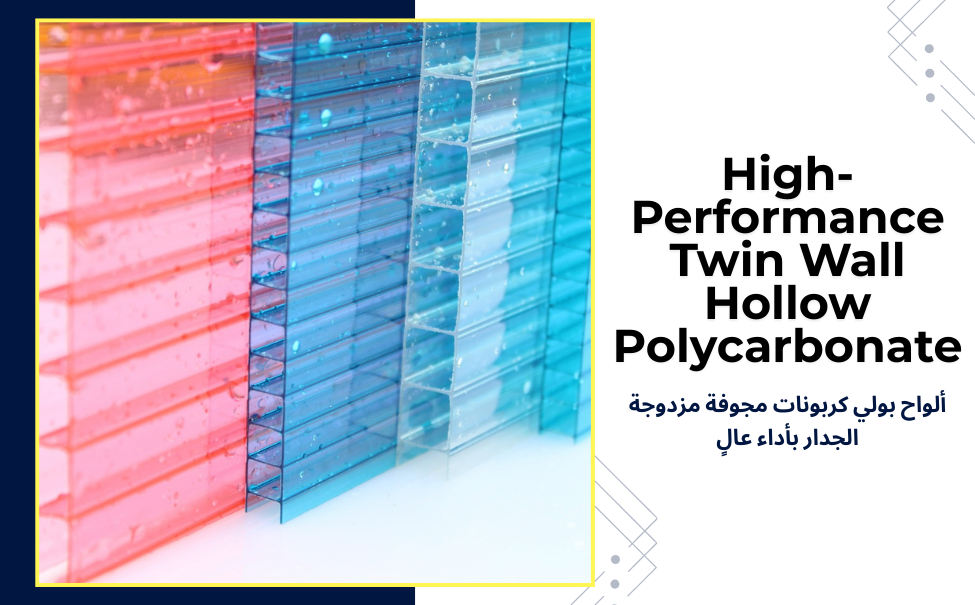

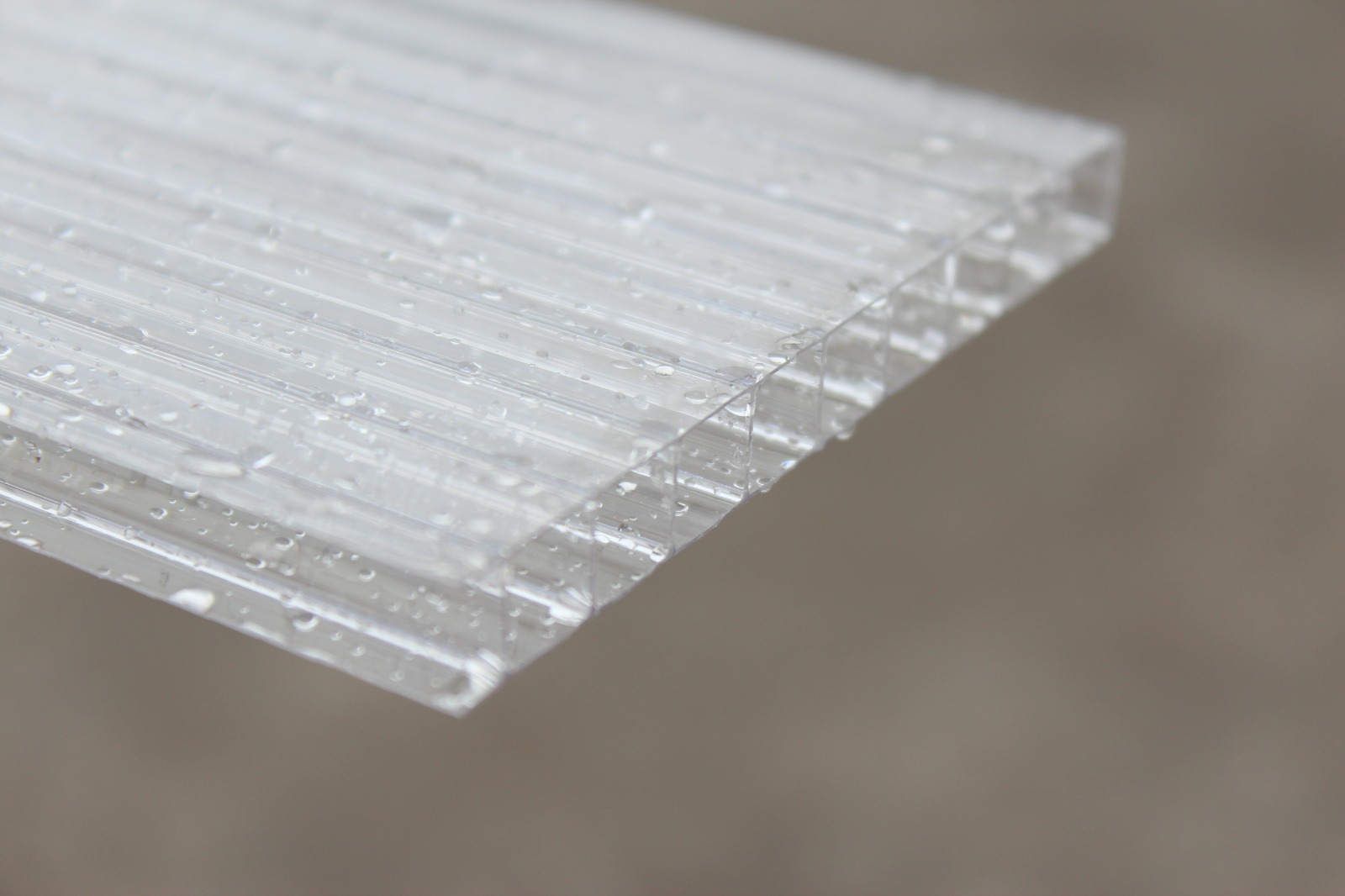

Extremely High Impact Resistance: Polycarbonate has about 250-300 times the impact strength of glass and about 30 times that of acrylic (PMMA). This makes it virtually unbreakable and highly resistant to vandalism, hail, and flying debris.

High Tensile Strength: Excellent load-bearing capacity, suitable for roofs and canopies in areas with moderate snow loads.

- Thermal Insulation

Low U-Value (High Thermal Resistance): The hollow chambers trap still air, creating a highly effective thermal barrier. Multiwall sheets (2-wall, 3-wall, 4-wall, etc.) offer progressively better insulation.

Energy Efficiency: Significantly reduces heat loss in winter and heat gain in summer, leading to lower energy costs for heating and cooling in buildings.

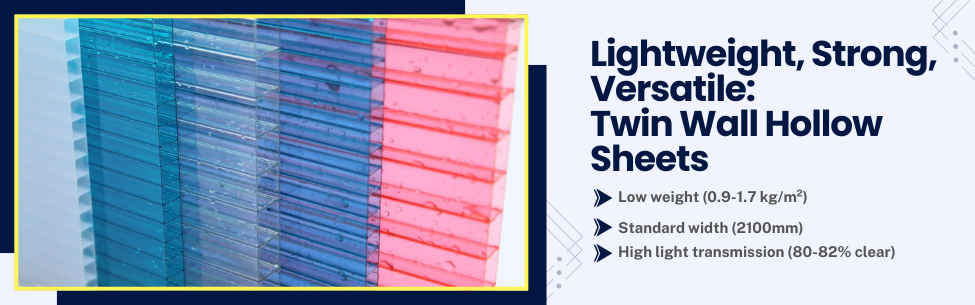

- Light Transmission & Optical Properties

High Light Transmission: Can transmit up to 80-90% of visible light (depending on thickness and number of walls), providing excellent natural daylighting.

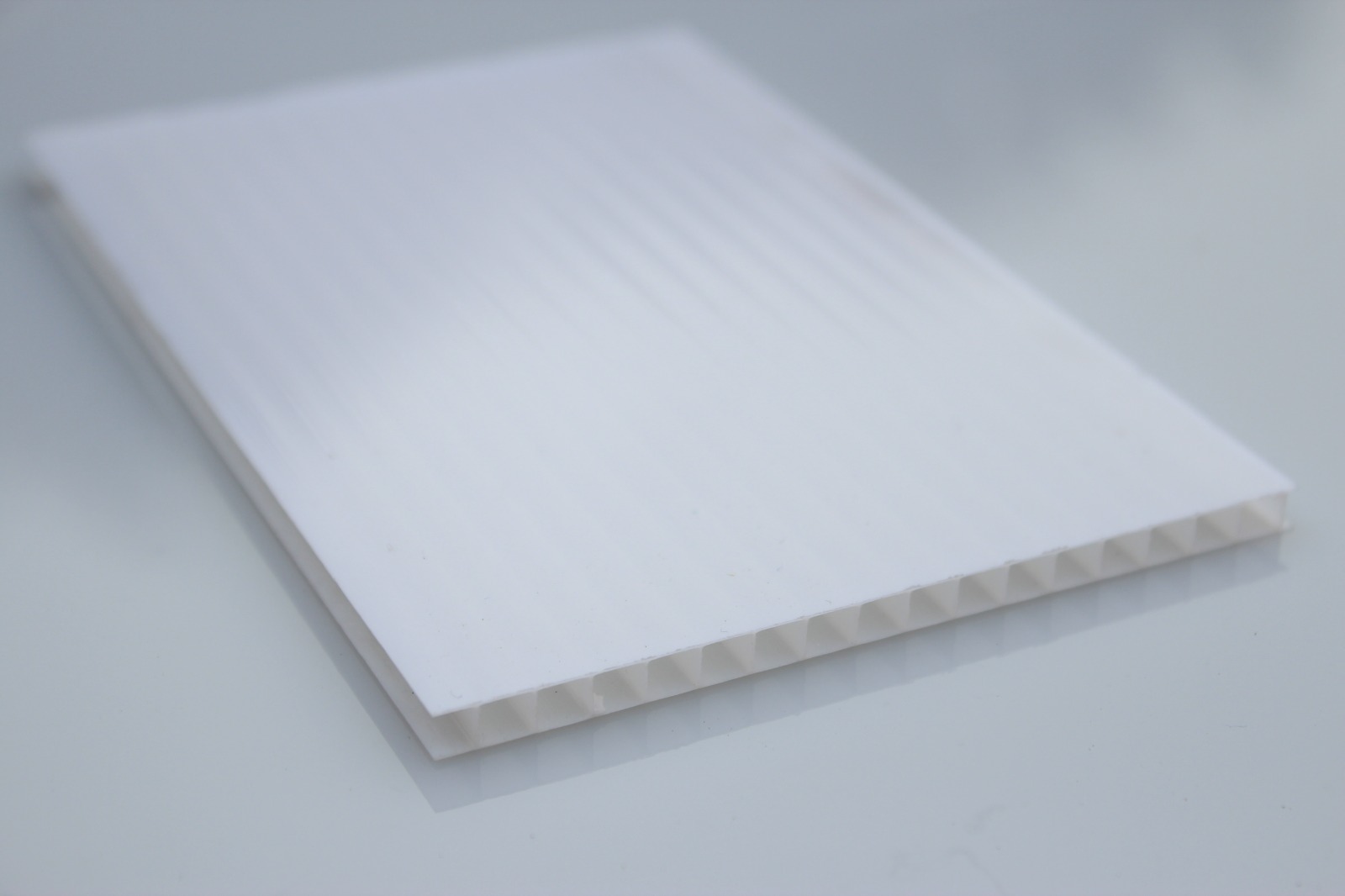

Diffused Light Option: Available in opal/translucent finishes that scatter light, eliminating harsh shadows and glare—ideal for greenhouses and skylights.

UV Protection: Almost all quality sheets are co-extruded with a UV-resistant layer on the top surface. This layer blocks harmful UV rays, protecting both the sheet from yellowing/brittleness (ensuring long-term strength and clarity) and the contents/people underneath.

- Lightweight & Easy Installation

Very Low Weight: Approximately 1/6 the weight of glass and 1/2 the weight of acrylic for the same area. This reduces structural support requirements and simplifies handling and installation.

- Fire Safety

Flame Retardant: Polycarbonate is inherently a B1 / Class A rated material (according to various international standards like UL94, DIN). It is self-extinguishing, has a high ignition temperature, and does not drip burning particles.

- Weather & Chemical Resistance

Excellent Weathering: With the UV protective layer, sheets have a long service life (typically 10-15+ year warranties against yellowing and hail). They withstand extreme temperatures (-40°C to +120°C).

Good Chemical Resistance: Resists many dilute acids, aliphatic hydrocarbons, and alcohols. However, it can be attacked by strong bases, concentrated acids, and some solvents.

- Flexibility & Design

Cold Bending: Can be cold curved on-site to a minimum radius (specified per thickness), allowing for arched structures without heat or special tools.

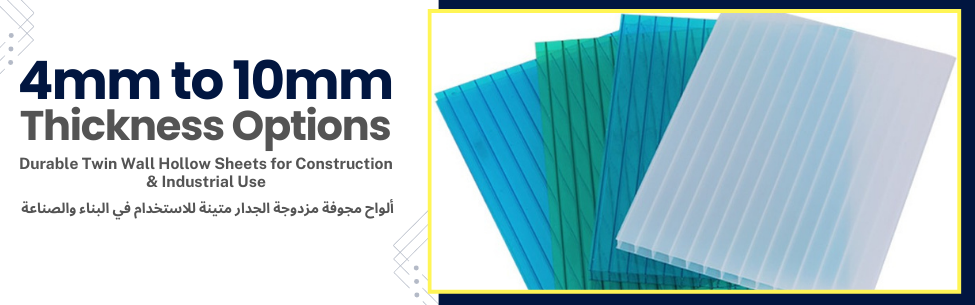

Technical Specifications & Variables

Feature Typical Range / Options Impact on Performance

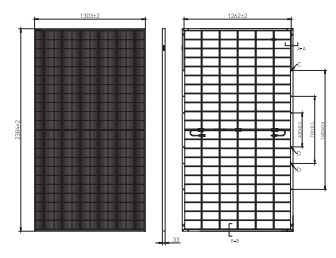

- Thickness 4mm, 6mm, 8mm, 10mm, 16mm, 25mm, etc. Thicker = higher insulation, higher load capacity, lower light transmission.

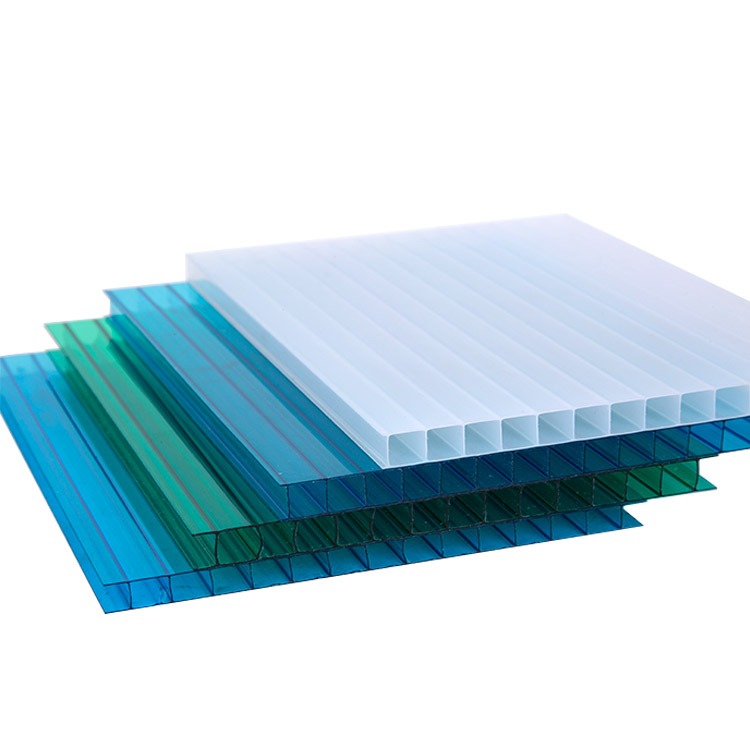

- Number of Walls 2-wall, 3-wall, 4-wall, 5-wall, X-structure. More walls = better thermal insulation (lower U-value) and increased rigidity.

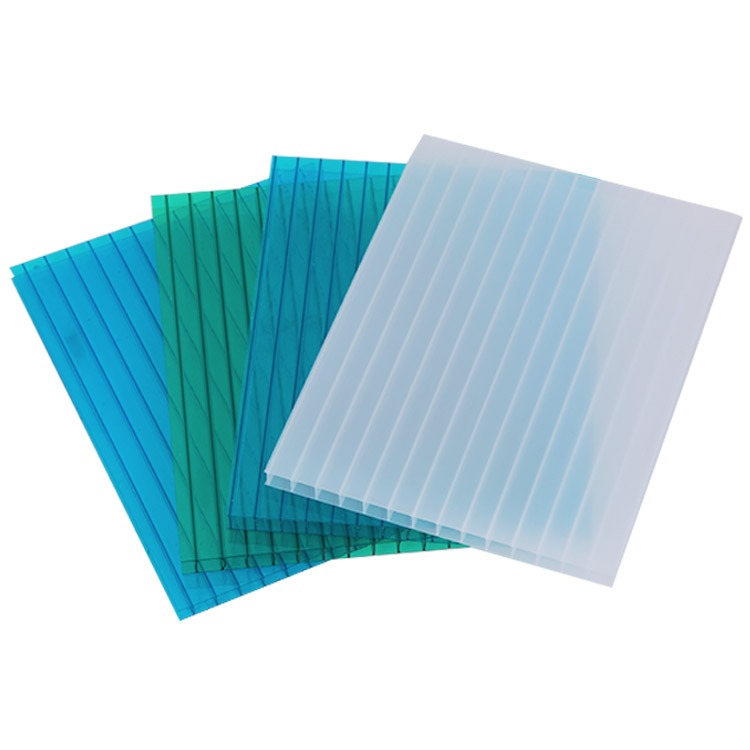

- Standard Colors Clear, Opal (milky white), Bronze, Grey, Green, Blue. Color affects light transmission and solar heat gain. The opal provides diffused light.

- Sheet Size Standard widths: 2100mm, 1050mm. Lengths: Custom, up to ~12m.Affects design and installation of joints.

- Surface Treatments One-Side: Standard for exteriors.

UV Two-Side: For canopies/glazing where both sides are visible.

Anti-Condensation: Interior coating reduces drip formation.

Critical for long-term performance and specific applications. - U-Value Ranges from ~3.5 W/m²K for 6mm 2-wall to ~1.0 W/m²K for 16mm 5-wall. Key metric for thermal insulation performance.

- Light Transmission From ~90% (4mm clear) to ~50% (16mm opal). Determines brightness and solar heat gain.

Reviews

There are no reviews yet.